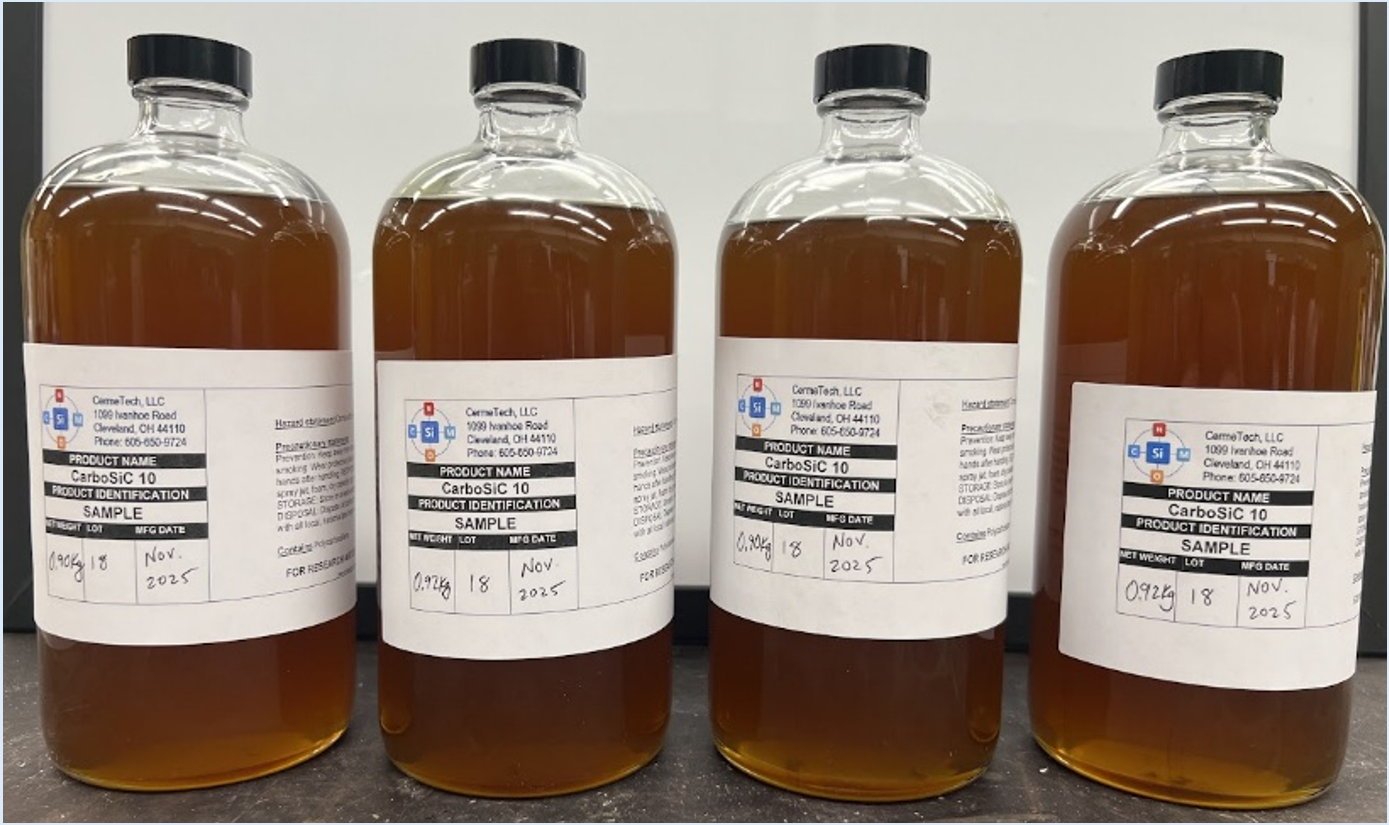

CarboSiC™10 - Polycarbosilane Preceramic Polymer

CarboSiC 10 is a silicon-carbide (SiC) precursor engineered for the fabrication of ultra-high-temperature SiC ceramic composites. It enables exceptional retention of structural integrity and mechanical performance at temperatures exceeding those achievable with any other commercially available SiC-forming precursor.

This performance is driven by the highly uniform and robust covalent bonding between silicon and carbon atoms within the resulting SiC lattice. Upon conversion, CarboSiC 10-derived SiC ceramics exhibit low coefficients of thermal expansion and high thermal conductivity, properties that are critical for managing extreme thermal gradients and intense heat fluxes in demanding operating environments.

Owing to its exceptionally high polymer purity, CarboSiC 10 achieves a near-stoichiometric 1:1 silicon-to-carbon yield during conversion. As a result, the final SiC ceramic demonstrates outstanding phase stability and oxidation resistance, demonstrated to maintain structural and thermal performance in atmospheric service temperatures exceeding 1800 °C.

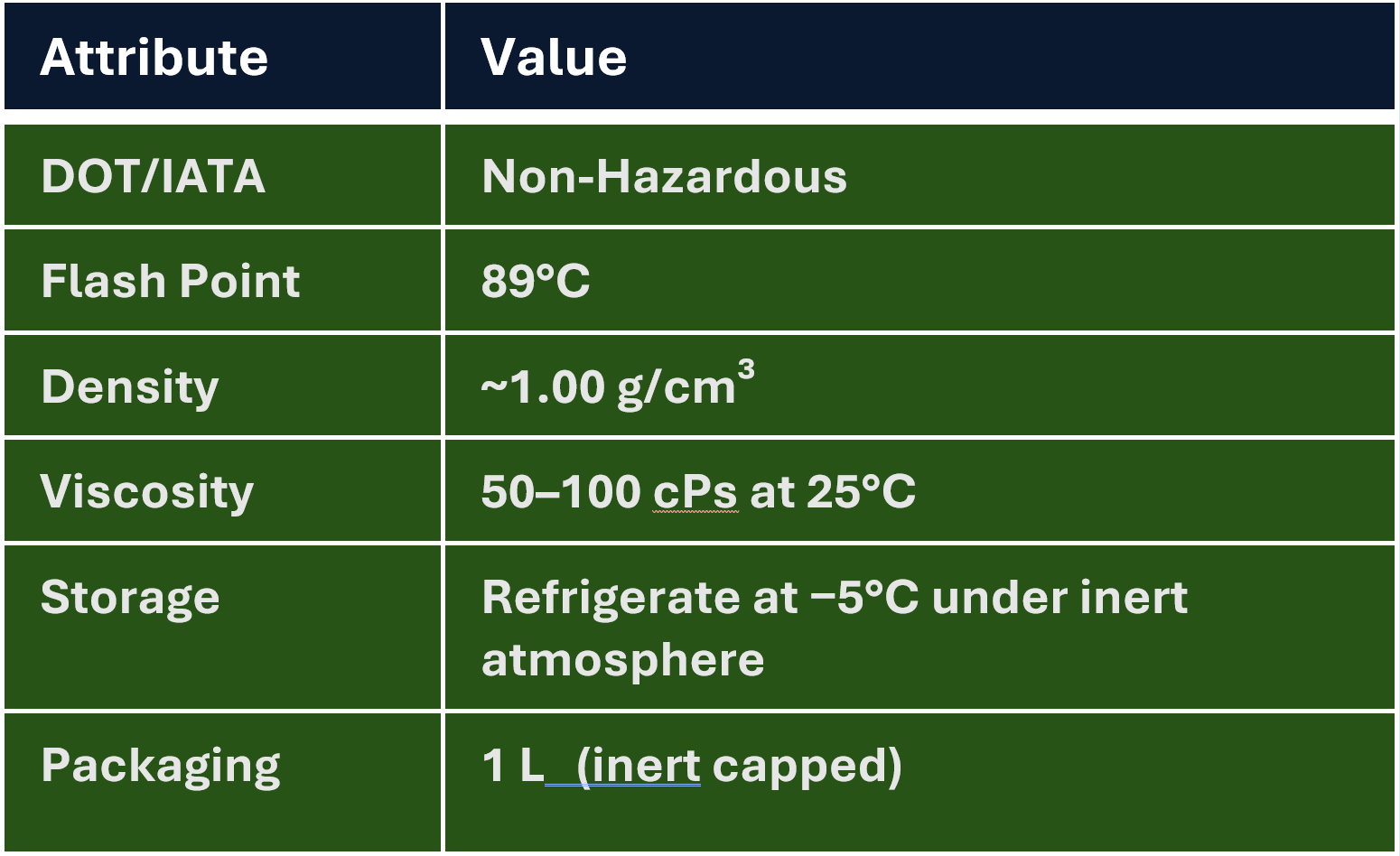

CarboSiC™10 Product Data and Material Safety Data are available upon request

The user must verify suitability based on their process conditions and application. The statements and properties provided are for reference only and are not guaranteed. CermeTech LLC. All rights reserved.